Pricing Factors for Commercial Generator Maintenance

Understanding the factors influencing the cost of commercial generator service is essential for effective budgeting and maintenance planning. This page provides detailed insights into pricing components, service variations, and related costs.

Larger generators with higher capacity typically incur higher service costs due to complexity and parts involved.

Service costs vary based on the location of the generator and ease of access, affecting labor and transportation expenses.

Routine maintenance tends to be less costly than emergency repairs or extensive overhauls, influencing overall expenses.

| Service Aspect | Estimated Cost Range |

|---|---|

| Basic Maintenance (oil change, filter replacement) | $200 - $500 |

| Preventive Inspection | $300 - $700 |

| Emergency Repair | $1,000 - $5,000 |

| Engine Overhaul | $4,000 - $15,000 |

| Parts Replacement (alternator, batteries) | $500 - $3,000 |

| Fuel System Service | $400 - $1,200 |

| Cooling System Service | $300 - $1,000 |

| Electrical System Check | $250 - $600 |

The cost of commercial generator service varies significantly based on the scope and complexity of required work. Routine maintenance is generally predictable, allowing for scheduled expenses that help prevent costly breakdowns. Emergency repairs, however, can lead to substantial costs due to urgent labor, parts, and potential downtime. Proper planning and regular inspections can optimize service expenditures and ensure reliable operation.

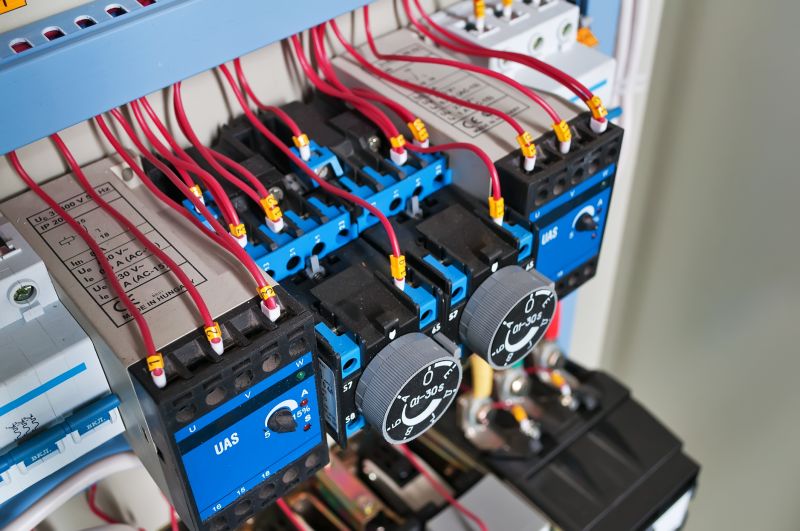

Costs for servicing electrical systems include diagnostics, repairs, and replacements of control panels and wiring.

Engine repairs or replacements constitute a significant portion of service costs, especially for major overhauls.

Maintaining cooling and fuel systems is vital for optimal performance and involves specific service costs.

| Related Service | Average Cost |

|---|---|

| Generator Installation | $5,000 - $20,000 |

| Extended Warranty Plans | $1,000 - $4,000 annually |

| Remote Monitoring Setup | $2,000 - $6,000 |

| Generator Decommissioning | $1,500 - $4,000 |

| Fuel Tank Inspection | $300 - $800 |

| Load Bank Testing | $1,000 - $3,000 |

| Battery Replacement | $150 - $400 |

| Transfer Switch Installation | $2,000 - $8,000 |

| Generator Relocation | $4,000 - $12,000 |